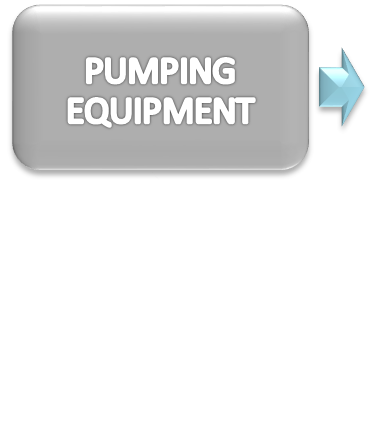

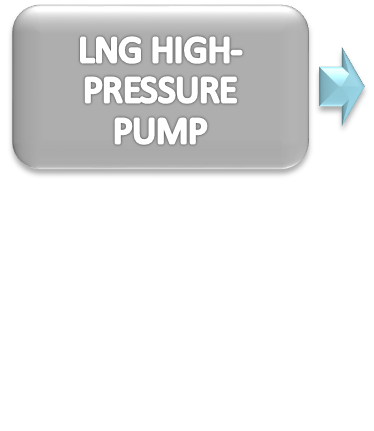

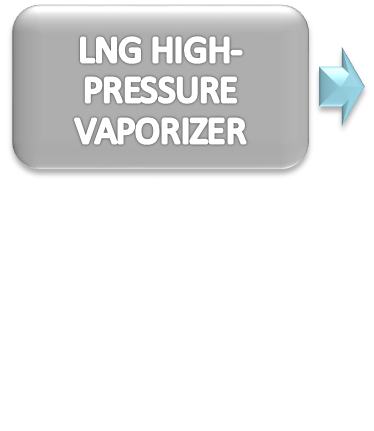

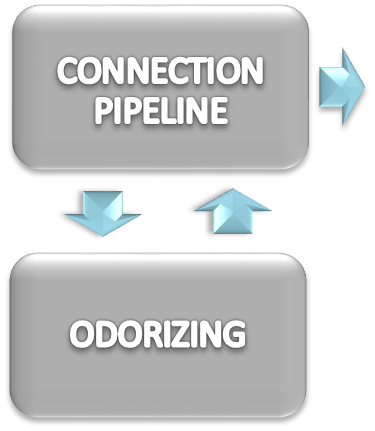

The main components of an LCNG station

- pumping equipment ensuring safe pumping from supply trailer to the stationary storage tank of the station

- LNG storage tank, vertical or horizontal LNG tank with a volume of 20 to 120 m3, vacuum insulated – max. pressure of 11 or 18 bar

- vaporizer (saturation) ensuring an increase in the pressure in the tank to the required values (to the saturated vapors pressure)

- high pressure pump, usually a piston type, providing LNG supplies to the high-pressure evaporator

- high-pressure evaporator ensuring changes from liquid to gaseous and heating of gas (CNG) to a temperature suitable for use in subsequent CNG technologies

- odorization unit for gas odorization (LNG is not odorized)

- CNG storage tank is divided into 2 or 3 sections and is equipped with a priority panel for the control of dispensing

- filling equipment – CNG dispenser for filling vehicle tanks with compressed natural gas

- control and monitoring system securing the traffic control and the station parameters control

Block diagram of typical L-CNG station

Questions?

Do you want to ask us something? Write us. Our specialist will respond to your inquiry within 1 week.